what is hpmc ?

More to visit our website : www.chinahpmccellulose.com , welcome to visit our factory .

HPMC Construction Grade

HPMC Construction Grade

Hydroxypropyl methyl cellulose (HPMC) is a natural polymer materials as raw materials,through a series of chemical processing and prepared non-ionic cellulose. It contains almost methyl cellulose(MC) of all the performance, your first choice for production of high quality building materials additives.To meet the needs of environmental protection, Our product with high water retention, dispersion, good fineness, good work ability, easy dissolution characteristics.It suitable for dry mortar building, both inside and outside wall putty powder milk (cream), adhesives, caulks, interface agents, coatings, self-leveling agent of new building materials.

Appearance: White powder.

Particle size: 98.0%min through 100mesh.

Charring temperature: 280-300 Deg.C.

Bulk density: 0.25-0.70g/cm3(Usually around 0.5g/cm3)

Real specific gravity: 1.26-1.31

Browning temperature: 190-200 Deg.C.

Surface tension (2% water solution):42-56 dyn/cm.

Product properties

1. Water Retention: The water retention will be enhanced, which is helpful with such problems as cement or gypsum construction material drying too fast and poor hardening or cracking due to insufficient hydration.

2. Operationality: It can enhance the plasticity of mortar and improve the coating efficiency in construction projects.

3. Adhesivity: It can make mortar attach to base material better since the plasticity of mortar is enhanced.

4. Slip Resistance: It can prevent slipping problem between mortar and the base material in construction project as a result of its thickening effect.

Product Parameters

| Product name | Hydroxy propyl methyl cellulose (HPMC) |

| Content of methoxyl | 24.0 - 30.0 |

| Content of hydroxy propyl | 9.0 - 12.0 |

| Temperature of gelation | 63℃ - 75 ℃ |

| Moisture | ≦5% |

| Ash | ≦5% |

| PH value | 7 - 8 |

| Appearance | white powder |

| Fitness | 80-100 mesh |

| Viscosity | 4,000 to 200,000 it can be customized |

| HPMC increased with methoxy content reduce, the gel point water solubility and surface activity also declind, depends on customer's situation. | |

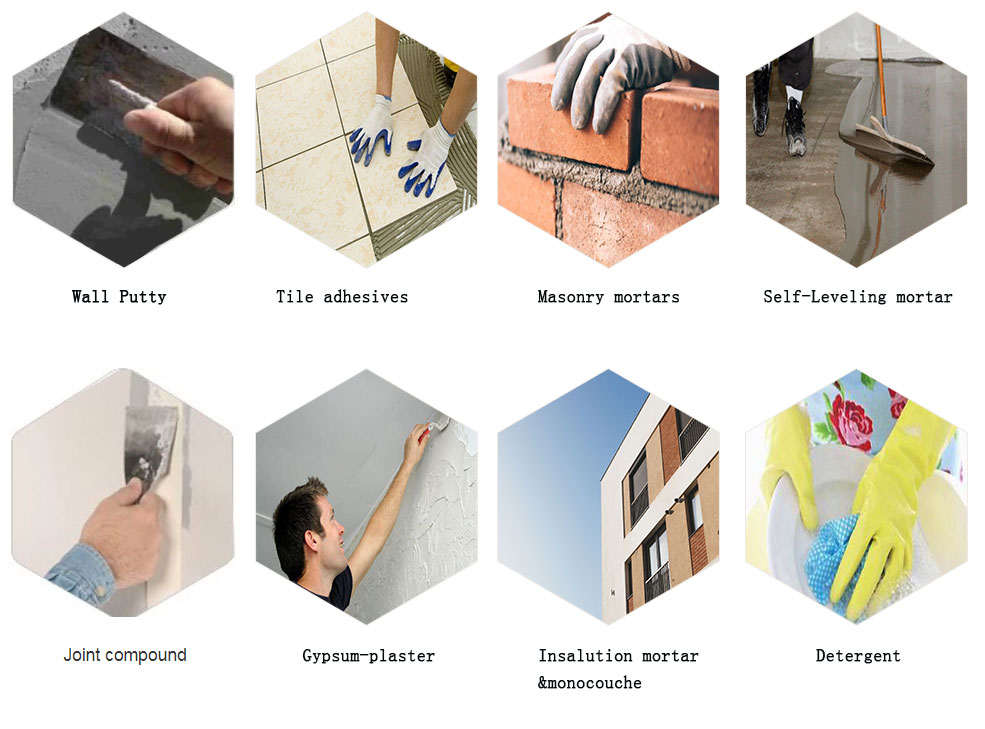

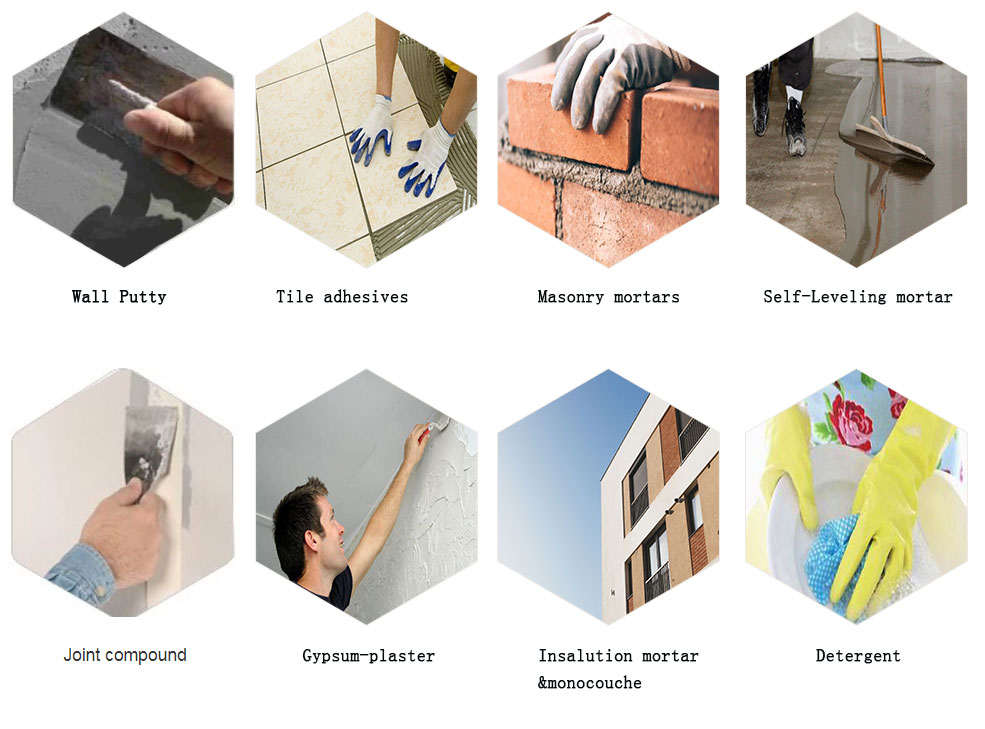

Application:

- Tile Adhesive

- Gypsum based skim coat

- Paste water resistant putty

- Dry-mixed plastering mortar

- Masonry mortar

- Joint filler

Packing and Storage

Standard Packing: In 25kg bags

Store it in a cool, dry place below 30degree and protected against humidity and pressing, since the goods is thermoplastic, storage time should not exceed six months.

Quantity/20GP:12Tons with pallets,14tons without pallets

Quantity/40GP:24Tons with pallets ,28tons without pallets

http://www.chinahpmccellulose.com/cellulose/hpmc/hpmc-construction-grade.html

Hydroxypropyl Methyl Cellulose (HPMC) is a non-ionic cellulos

Hydroxypropyl Methyl Cellulose (HPMC) is a non-ionic cellulos

Praduct technical data

Viscosity Table of Normal Grades of HPMC:

| Grade | Viscosity (mPa.s) | |

| MP-A | MP-B | |

| 400 | 300-500 | — |

| 4K | 3200-4800 | — |

| 10K | 8000-12000 | — |

| 20K | 16000-24000 | 16000-24000 |

| 40K | 32000-48000 | 32000-48000 |

| 60K | 48000-72000 | 48000-72000 |

| 100K | 80000-120000 | 80000-120000 |

| 150K | 120000-180000 | 120000-180000 |

| 200K | ≥160000 | ≥160000 |

| Note: | ||

| 1. Viscosity: Brookfield LVT Viscometer (2% dry, 20°C). | ||

| 2. All above models are available for surface treatment type. | ||

Application Table of HPMC

| Grade

Application |

400 | 15K | 20K | 40K | 60K | 100K | 150K | 200K |

| Floor Self-leveling compounds | ●● | |||||||

| Skim Coat, | ●● | ●● | ●● | ●● | ● | |||

| EIFS adhesive mortar | ●● | ●● | ●● | ●● | ||||

| EIFS Base Coat | ●● | ●● | ●● | ●● | ● | |||

| Tile Adhesive | ●● | ●● | ●● | |||||

| Tile grouts, Joint filler | ●● | ●● | ● | |||||

| Renders, Plasters, masonry mortar | ●● | ●● | ●● | ● | ||||

| Sealing Slurries | ●● | ●● | ●● | ●● | ||||

| Waterproof mortar | ●● | ●● | ||||||

| Interface Agent (primer) | ●● | ● | ● | |||||

| ●: Recommended. ●●: Highly Recommended.

The suggestion is not regard as as guarantee or their suitability for a particular application. The information on the use of our products should be suitable to local conditions and the materials employed. |

||||||||

Water-soluble and thickening ability: This product can be dissolved in cold water to form a transparent viscous solution.

HPMC for Construction Mortar

HPMC for Construction Mortar

Specifications

|

Items |

HPMC |

|

Methoxyl content (-OCH3) w/% |

20.0-28.0 |

|

Hydroxypropyl content (-OCH2CHOOHCH3),w/% |

5.0-11.0 |

|

Gelling temperature(°C) |

55-80 |

|

Moisture content, w/% |

MAX 1% |

|

Residue on ignition, w/% |

MAX 1.5% |

|

Lead(Pb), ppm |

MAX 2 |

|

Arsenic (As), ppm |

MAX 2 |

|

Heavy metal |

MAX 20 |

|

Viscosity (mpa.s) |

5-200000 |

HPMC Hydroxypropyl Methylcellulose

HPMC Hydroxypropyl Methylcellulose

HPMC Hydroxypropyl Methylcellulose specifications:

|

Item |

Standard |

|

Appearance |

white powder |

|

Methoxy content ,% |

19.0-24.0 |

|

Hydroxypropyl content,% |

≥10 |

|

Viscosity,mpa.s |

80000-200000 |

|

Moisture ,% |

≤5 |

|

Residue (Ash) ,% |

≤5 |

|

PH Value |

5-7 |

|

Fineness, mesh |

80-120 |

|

Storage |

in the shade |

|

Packing |

25kg per bag |

Hydroxypropyl MethylCellulose (HPMC)

Hydroxypropyl MethylCellulose (HPMC)

| COMMON NAME | HYDROXYPROPYL METHYL CELLULOSE |

| ABBREVIATION | HPMC |

| CAS NO. | 9004-65-3 |

| STANDARDS COMPLIANT | ENTERPRISE STANDARD |

| CHEMICAL FORMULA | R=CH2CH(CH3)OH |

Hydroxypropyl Methyl Cellulose (HPMC) PHYSICAL AND CHEMICAL PROPERTIES

* Particle size: 98.5% passes through 100 mesh; 100% passes through 80 mesh.

* Charring temperature: 280-300℃.

* Bulk density: 0.25-0.70 g/cm3 (Usually around 0.5 g/cm3 )

* Real specific gravity: 1.26-1.31.

* Browning temperature: 190-200℃.

* Surface tension: (2% water solution) 42-56dyn.cm.

* Properties: Dissolved in water and some organic solvent such as ethanol. propyl alcohol. ethylene chloride, the water solution is of surface activity. It is a nonionic surface active agent. Gelation temperature is different for different grades. For example, among 60RT Hydroxypropyl Methylcellulose, 60 is gelation temperature, Namely, 2% water solution will form gelation at 60%.

| Appearance | White or off-white powder |

| Methoxy ( % ) | 19.0~ 24.0 |

| Hydroxypropoxy ( % ) | 4.0 ~ 12.0 |

| pH | 5.0~ 7.5 |

| Moisture ( % ) | ≤ 5.0 |

| Residue on ignition ( % ) | ≤ 5.0 |

| Gelling temperature ( ℃ ) | 70~ 90 |

| Particle size | min.99% pass through 100 mesh |

Hydroxypropyl MethylCellulose (HPMC) Application

Hydroxypropyl Methyl Cellulose specification

Hydroxypropyl-MethylCellulose-HPMC-MSDS

What is hydroxypropyl methyl cellulose HPMC ?

What is hydroxypropyl methyl cellulose HPMC ?

Hydroxypropyl methyl cellulose as a white or off-white powder, soluble in water and some solvents, soluble in water and some solvents, HPMC also has thickening ability, the hydroxypropyl methyl cellulose (HPMC) into water After, the formation of transparent colloid, see the transmittance, the better the larger the transmittance, which illustrate insolubles less. Vertical reactor transparency in general are good, horizontal reactor to be satisfactory, but can not explain the quality of legislation kettle pot production would produce better than lying, there are many factors that determine the quality of products.

Application

|

Product Name

|

HPMC

|

|

Content of Methoxy

|

24.0-30.0

|

|

Content of Hydroxypropyl

|

9.0-12.0

|

|

Temperature of Gelation

|

50-68℃

|

|

Moisture

|

≤5%

|

|

Ash

|

≤5%

|

|

PH Value

|

7-8

|

|

Apperance

|

White Powder

|

|

Fitness

|

80-100List

|

|

Viscosity

|

100,000 to 200,000 it can be custmized

|

|

Re:HPMC increased with methoxy content reduce, the gel point,water solubility and surface activity also declined, depends on coustomers' situation

|

|